The Use of Power Over Ethernet (PoE) in Manufacturing

In 2003, when IEEE introduced the first ethernet standard, manufacturers and other large enterprises considered it a less-reliable technology. It provided 15 watts of power, limiting its use to energy-efficient network devices like surveillance cameras, IP phones, Wi-Fi routers, networked audio, and wireless access points.

Nonetheless, the modern PoE in manufacturing provides up to 90 watts of power and 1000 Mbps of data transfer rates, making it suitable for full-scale, commercial use. Enterprises can use it to run power-hungry devices like HVAC controllers, door access systems, video conference equipment, LED lighting systems, and more.

In addition, the PSEs and PDs used in Power over Ethernet are hardened for use in harsh environments, especially those characterized by vibrations, heat, cold, and dirt. Versa Technology, a firm supplying networking hardware, has evaluated PoE to help progressive manufacturers take advantage of this disruptive technology.

What Is PoE?

PoE is a technology for an ethernet cable network to provide both power and data transfer to networking devices used in a business, industrial, or residential setting. With this technology, enterprises don’t have to install separate cabling networks for electricity and data, as was the case a few years ago.

PoE Brief History

PoE technology came into the limelight around 2003, when IEEE released its first standard. However, that is not when it was in the development process. Cisco’s developers established its proprietary version in 2000.

At its inception, Power over Ethernet provided 7 watts to power IP phones, a reason it was not popular. It grew popular when developers released newer standards with more wattage and high data transfer rates.

Since then, the number of commercial and governmental facilities using PoE has been shooting up yearly. For instance, reports show that since 2020, the value of Power over Ethernet has been growing at a CAGR rate of 12.6%.

Thousands of enterprises in the world’s healthcare, mining, manufacturing, energy, and utility sectors are increasingly adopting the technology.

PoE Circuitry Overview

A basic PoE circuit consists of three major parts: power sourcing equipment (PSE), cabling network, and powered devices (PD). Each part plays a different role, helping PoE provide electricity and seamless data transfer.

The power sourcing equipment provides the power that network devices need. That means, without the PSE equipment, an ethernet cabling system will not provide the power required to run PoE-ready surveillance systems, automation sensors, computers, or phones.

The PD is an umbrella term for all networking equipment that consumes power from the dual-purpose ethernet cabling. In manufacturing, powered devices include IP cameras, network routers, lights, access control components, and point-of-sale kiosks. Powered devices might also include controllers, meters, digital signage, computer monitors, LCD TVs, and laptops.

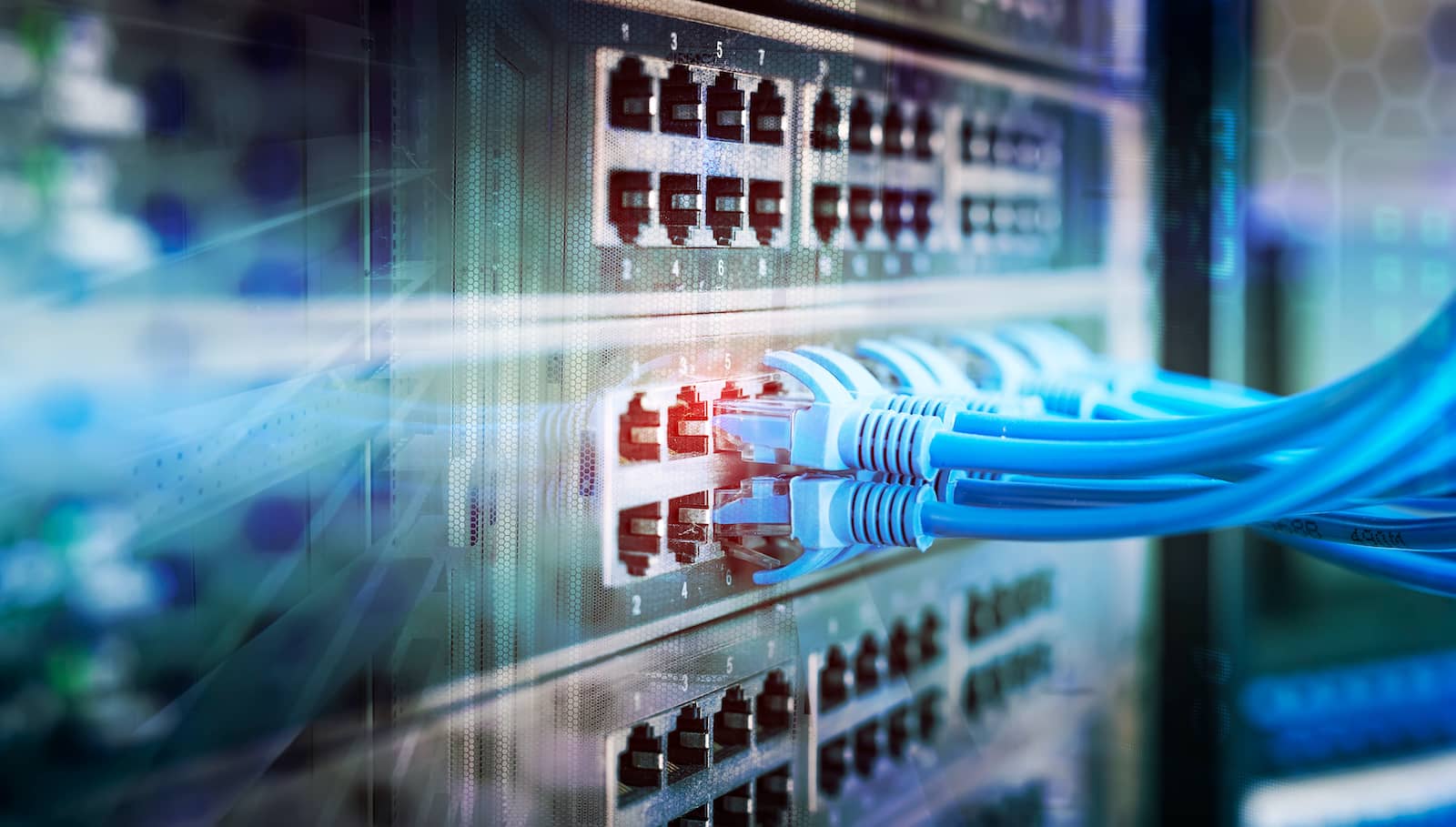

On the other hand, the cabling network provides a channel through which electricity and data flow. Typically, PoE circuitries use ethernet cabling with CAT5e, CAT3, CAT8, CAT6, or CAT6e standards. The choice of cable depends on the data transfer speeds and wattage the consumer needs.

How Does PoE in Manufacturing Work?

Generally, Power over Ethernet works like a normal electric or ethernet cabling network. The only significant difference is that PoE is a dual-function circuitry sending power and transferring data through a single cable.

Since PoE uses regular ethernet cables, manufacturing companies with an existing system don’t have to install new cable networks. All they need is to upgrade the existing network with hardware like switches, extenders, splitters, and hubs to fit the company’s power and data transfer needs. A PoE technician will check the existing PoE system and suggest the necessary upgrades.

On the other hand, companies that lack an existing ethernet cabling network must install a new one that meets the CATx standards. Unlike electric cabling, ethernet cables have four pairs of twisted cables, two pairs transmitting data and the other two channeling electric power.

After installing the PoE cabling network, the enterprises can use the system like ordinary electric ethernet circuitry. They need to plug their powered devices into suitable PoE switches and enjoy the benefits of PoE.

What Are the Four Types of PoE?

Since 2003, when IEEE approved the first standard of PoE, developers have since released three more standards, each providing more power and improved data transfer rates. With the available standards, small or large manufacturing companies can install a Power over Ethernet protocol that meets their exact needs.

Here is a detailed overview of each PoE standard available for consumers.

PoE Type 1: IEEE 802.3af

PoE type 1 is the first standard established around 2003. This type of PoE produces a maximum port power of 15 watts, enough for powering low-voltage networking systems like IP cameras, networked audio, static surveillance cameras, VoIP phones, and access points.

This PoE standard uses a CAT3 ethernet cable with a base data transfer rate of 10 Mbps. With the low voltage and data transfer rates, IEEE 802.3af is suitable for small-size companies that need power for a few network devices like IP phones and surveillance cameras.

Although it operates efficiently, this PoE in manufacturing standard has one downside: It is not ideal for large companies that need enough voltage for power-hungry power equipment or those that need maximum data transfer rates.

PoE Type 2: IEEE 802.3at

Established in 2009, PoE type 2 is an advanced option to IEEE 802.3af. It provides a port power of 30 watts, enough to run moderate power consumers like remote computer terminals, IP telephones, access control, and PTZ cameras.

PoE type 2 uses a CAT5 ethernet cable with base data transfer rates of 100 Mbps. With the data transfer rates, this standard is ideal for small and medium-sized enterprises that need to send and receive files with reduced latency.

The IEEE 802.3at standard is backward compatible. That means enterprises can use it to run low-energy-consuming networking devices like wireless access points, static surveillance cameras, and networked audio.

PoE Type 3: IEEE 802.3bt 60W

The industrial grade PoE type 3 was released in 2018 to high-power energy-consuming network devices, especially those found in moderate to large businesses. Popular as PoE++, IEEE 802.3bt delivers a maximum port power of 60 watts.

The IEEE 802.3bt standard uses CAT5e internet cables to provide more power and data transfer speeds. Unlike CAT3 and CAT5 cables, CAT5e handles data transfer speeds of up to 1000mbp, giving companies the power to send and receive files in a record time.

With 60 watts of power, IEEE 802.3bt is suitable for powering high-voltage networked devices, including LED lighting, building management devices, wall-mounted clocks, network routers, IPTV decoders, and public address systems.

Like PoE type 2, type 3 is backward compatible. Manufacturing companies and other enterprises can use it to power energy-efficient systems using 15 or 30 watts of power or heavy-power consumers using 60 watts without safety issues.

PoE Type 4: IEEE 802.3bt 90W

Developers released PoE type 4 around the same period as PoE type 4. Also known as higher power PoE, the IEEE 802.3bt standard provides a maximum port power of 90 watts, enough for common networking devices like flat screens, laptops, computer monitors, digital signage, point of sale systems, and LCD TVs.

PoE type 4 runs on a CAT5e or other better ethernet cable like its predecessor. The cable offers up to 1000Mbps of data transfer speeds, an aspect that makes it ideal for enterprises that want seamless data transfer and communication.

Since this higher power PoE standard is backward compatible, manufacturers can use it to power all PoE-ready equipment, including those that consume low power. It is a great option for enterprises that wish to leverage the full power of PoE.

What Are the Benefits of PoE?

Power over Ethernet gained huge traction for one major reason: using a single, dual-purpose ethernet cabling network to provide power and data connection. With this capability, enterprises do not have to incur the expense of installing two separate cabling networks.

On average, technicians report that companies using PoE in manufacturing cut down Ethernet and electrical installation expenses by around 50%, a huge saving for large institutions and industries.

Besides eliminating the need for two cabling systems, PoE in manufacturing provides other benefits like:

Enhanced Safety

Power over Ethernet is super safe for legacy equipment and users alike. For instance, before powering equipment, PoE’s power sourcing equipment must determine the exact wattage to release to the end equipment.

After determination, the power sourcing equipment releases the exact amount of power that an end device requires. The power intelligence protects legacy equipment from short circuiting or blowing up. In return, enterprises using PoE spend little on equipment repair and replacement.

Power over Ethernet is safe for the handler since it passes around 44 to 57 volts of direct current, which is not lethal enough to cause fatalities. However, it can cause minor to moderate burns and pain.

On the other hand, the power-sourcing equipment cannot release power until it experiences a handshake. That is, the PSE has to determine the voltage the powered device requires. The PSE releases no power if the PD needs no power.

Power over Ethernet Is Highly Economical

Power over Ethernet is economical in many ways. First, PoE’s dual-purpose ethernet cable provides power and electricity, cutting labor and material costs by around 50%. Though the savings might appear low, large companies can save thousands of dollars that could have been spent buying material and hiring technicians to install two cabling systems.

Second, Power over Ethernet allows for economical use of space. It minimizes the space ethernet, electrical cables, and hardware could have consumed. Furthermore, the PoE circuitry powers devices with one single cable, eliminating the use of power and data cables. The elimination of extra cables does not only save space but also makes workspaces appear less cluttered.

Third, Power over Ethernet is energy efficient. How? The groundbreaking technology fosters the use of power-efficient LED lighting, HVAC controllers, surveillance cameras, sensors, monitors, and access control systems. In most cases, PoE-ready devices are smart systems that can automatically power off when not in use and when needed.

Power over Ethernet Is Standard-based

Like many electrical devices and systems, PoE is standard-based. That means PoE consumers can purchase hardware from various vendors and use them to make a PoE circuitry that works harmoniously. Such standardization gives enterprises the power to shop around for fair deals from various vendors.

Also, standardization allows the flexibility to relocate various PoE-powered systems when needed. For instance, if a surveillance camera is not strategically placed, enterprises can detach and relocate it to a different place without incurring an extra expense. The enterprises will not need a new wiring system to accommodate the relocated powered device.

With standardization, Power over Ethernet does not just run PoE-ready devices. But, the groundbreaking tech has a PoE splitter that can power up non-PoE-ready devices. So, Power over Ethernet can run virtually all devices in a business setting. It can completely replace the use of standalone electrical and ethernet cabling networks.

PoE Is Highly Reliable

Between 2000 and 2003, when Power over Ethernet was taking its baby steps, consumers, especially large companies, regarded it as unreliable. It provided around 7 to 15 watts, which powered a few powered devices in a business setting. Bigger businesses had to use PoE alongside a dedicated electricity cabling network.

However, today, Power over Ethernet produces up to 90 watts, enough to power every system in a business setting. From digital signage, surveillance systems, and smart sensors, PoE provides the power and data transfer needed to run various network devices.

What’s more, PoE cabling and hardware’s design can withstand the harshest conditions in an industrial setting. For instance, a professionally installed PoE circuitry can withstand intense vibrations, high temperatures, dirt, and direct sunlight exposure.

PoE Is Scalable

The Power over Ethernet technology was built with scalability in mind. Growing enterprises can easily expand their dual-purpose cabling network to accommodate more powered devices whenever the need arises.

Since PoE is safe and easy to install, businesses do not need experienced technicians to handle their PoE expansion projects. Instead, they can use their in-house employees with basic technical skills to execute the projects.

Typically, PoE is a plug-and-go system. Therefore, companies’ technical teams must get the cables, extenders, splitters, and hubs. After securing the right hardware, the team will need to configure the system to accommodate more powered equipment.

Network Components Commonly Found in PoE Installations

A standard PoE installation has five central network components, including extenders, injectors, splitters, switches, and hubs. Each component mentioned is crucial in making a PoE circuitry operate seamlessly.

PoE Splitters

A PoE splitter is a component that supplies power to an end device that is not PoE-ready. After splitting power from data, it lets enterprises run both PoE-ready and non-PoE-read devices through the ethernet cable.

Without the splitter, enterprises would still have to use two cabling systems — one for PoE-ready devices and another for devices that cannot run on dual-purpose ethernet cables.

PoE Extenders

Just as its name suggests, a Power over Ethernet extender extends power beyond the usual 100 meters. Extenders are suitable for large buildings like academic campuses, shopping malls, corporate offices, and manufacturing companies that want to expand their PoE cabling network to other places.

PoE Switches

A PoE switch is like the socket used in electrical circuits. The PoE switch is where enterprises plug various network devices like sensors, TVs, laptops, phones, control access points, and computers whenever they need to use the appliances. The switch provides power and receives data from the end devices.

PoE Hubs

A PoE hub is a group of injectors with several data interfaces on one side and PoE interfaces on the other. The Power over Ethernet hubs send power from the switch to non-PoE network devices. Moreover, the PoE hubs send data from the non-PoE network devices to the switch.

PoE Injectors

A PoE injector is an adapter that connects a PoE device to a non-PoE Local Area Network switch. Mostly, technicians use the injectors to power systems installed in hard-to-reach places with an existing non-PoE switch.

Industrial Applications of PoE

With the ability to supply wattage of up to 90W and data speed of 1000 Mbps, PoE is a valuable resource for forward-looking manufacturers. Already a majority are using it to interconnect network devices that streamline day-to-day operations. However, interconnecting the network devices is not the only industrial application for Power over Ethernet in manufacturing. Other applications of this technology include:

Workplace Security

Power over Ethernet is an integral part of a company’s security systems. That is because it provides the power and connectivity needed by security systems like surveillance cameras and access control systems to function efficiently.

The dual-purpose ethernet cabling system saves companies the hassle of installing two separate cabling networks in hard-to-reach places where cameras will be installed. Furthermore, it provides the bandwidth security systems need to work seamlessly.

Indirectly, PoE plays a central role in minimizing equipment loss, giving employees a high sense of safety while running errands.

Building Automation

Automating processes is a dream for many forward-looking companies. It increases employee productivity, enhances occupational safety, and reduces factory lead times. Automation also improves product quality, and it leads to efficient use of company materials.

Power over Ethernet has proved to be one of the best technologies that give companies a strong head start toward automation. This disruptive technology provides the power and data connection needed to run automation systems like sensors, smart gadgets, and intelligent mechanical systems.

Furthermore, the Power over Ethernet interconnects the smart network devices used in automation. For example, the technology connects computers to sensors and HVAC sensors to a facility’s heating and air conditioning system.

Customer Service

PoE is central in improving customer support and boosting customer retention rates. How? The groundbreaking technology powers modern systems like point-of-sale kiosks, which reduce customer wait times, improve order accuracy, and relieve customer support during busy shopping.

Besides powering the point-of-sale kiosks, tech-savvy manufacturers use PoE to smart power signs used in large shopping complexes or manufacturing company floors. The signs guide customers through facilities, giving them a reason to keep using the savvy enterprise’s top services.

With improved customer satisfaction and retention rates, manufacturing companies using PoE make more sales and profits. The companies enjoy increased brand visibility, positive word-of-mouth, and improved brand visibility.

Workplace Communication

Cisco’s developers established the Power over Ethernet for one major reason: powering the IP phone used in communication. At inception, many manufacturing companies and large institutions used IP phones as the major communication channel.

Since then, Power over Ethernet has become the backbone of seamless workplace communication. The technology powers and interconnects computers to communicate and share files between various departments.

Moreover, PoE powers audio and visual systems like videoconferencing equipment and Wi-Fi routers. It also powers Bluetooth devices and other tools for conferencing and normal communication.

Workplace Collaboration

With Power over Ethernet in manufacturing’s high file transfer speeds, employees share crucial files in a jiffy. PoE also provides the data transfer speeds needed to operate online collaborative spaces like Slack, Trello, Asana, Microsoft 365, Podio, and Flock.

In return, the improved file sharing ability leads to improved problem-solving and employee productivity. In the bargain, the PoE-enabled collaboration increases a firm’s potential for growth and ability to adapt to change smoothly.

PoE on the Factory Floor

PoE does not just provide electricity and high file transfer speeds. But, it is built to endure harsh conditions, which are common in manufacturing and other commercial settings. Its cabling and hardware are built to work optimally in environments characterized by extremely high or cold temperatures. The components will not break down or malfunction easily, even when exposed to temperature extremes regularly.

Apart from extreme temperatures, industrial PoE is built to withstand other harsh environments like intense vibrations and exposure to corrosive chemicals. Also, PoE can withstand continuous exposure to damaging ultraviolet rays and other outdoor elements.

With the excellent endurance in demanding environments, Power over Ethernet technology stands as an ideal cabling system to supply power and data connection across multiple manufacturing and industrial settings like:

- Chemical manufacturing companies.

- Food and drink companies.

- Heavy equipment manufacturing plants.

- Mining companies.

- Oil and gas production firms.

- Utility companies.

- Textiles and clothing.

- Transport equipment manufacturers.

Get Your PoE Supplies From Versa Technology

PoE is no longer an unreliable technology powering a few low-energy-consuming systems like VoIP phones, static surveillance cameras, and Wi-Fi routers. But, it is a highly reliable source of power and data transfer for full-scale industrial use. Manufacturing companies, institutions, and other enterprises use it to power smart LED lighting, large LCD screens, point-of-sale kiosks, and security systems. Moreover, enterprises use PoE to run advanced automation and access control systems.

Since the integrity of PoE installation depends on the quality of hardware you get, make sure you buy from reputable technology firms. Versatek Technology is the industry leader when it comes to supplying PoE hardware. We offer high-quality injectors, switches, surge protectors, extenders, converters, cables, media converters, and other hardware needed to install a fully working PoE system. Contact us to learn about everything you need to set up your PoE in manufacturing.

- The Use of Power Over Ethernet (PoE) in Manufacturing

- What Is PoE?

- How Does PoE in Manufacturing Work?

- What Are the Four Types of PoE?

- What Are the Benefits of PoE?

- Network Components Commonly Found in PoE Installations

- Industrial Applications of PoE

- PoE on the Factory Floor

- Get Your PoE Supplies From Versa Technology