Circular Economy

Sustainable product design, throughout the entire lifecycle and beyond

An economy is the wealth and resources of a country or region, especially in terms of the production and consumption of goods and services. Most of us are familiar with the ‘take-make-waste’ linear model, where growth results from the consumption of finite resources.

Companies extract and harvest natural materials and use them to manufacture products that are sold to consumers. Individuals discard the products when they are no longer of use. This linear model of economic growth has been accelerating since the start of the Industrial Revolution.

According to the World Economic Forum, the following trends are an indication that the linear model may be reaching its limits.

- The risk to the security and safety of global supply chains is increasing.

- Price volatility for consumer goods was higher in the first ten years of the 21st century than ever before.

- Agricultural productivity is slowing.

- Soil fertility is declining.

- Industries are struggling to find needed virgin resources such as water, land, or atmosphere.

Recently, the world came face-to-face with the risks associated with a linear economic system where resource prices increase and supply chains are disrupted.

An alternative to a linear economy is a circular one where products can be reused, repaired, and remanufactured. In the tech world, the materials used in networking hardware can be reused. Intelligent sensors can optimize energy efficiency. Converting more last-mile networking to Power over Ethernet (PoE) technologies reduces the number of power cords and the complexity of the electrical infrastructure.

Internet of Things (IoT) technologies can contribute to a circular economy through the intelligent deployment of devices. These devices collect data to enable responsible decisions to be made about resource use. Designing IoT devices using materials that can be reused is another way technology can contribute to a circular economy.

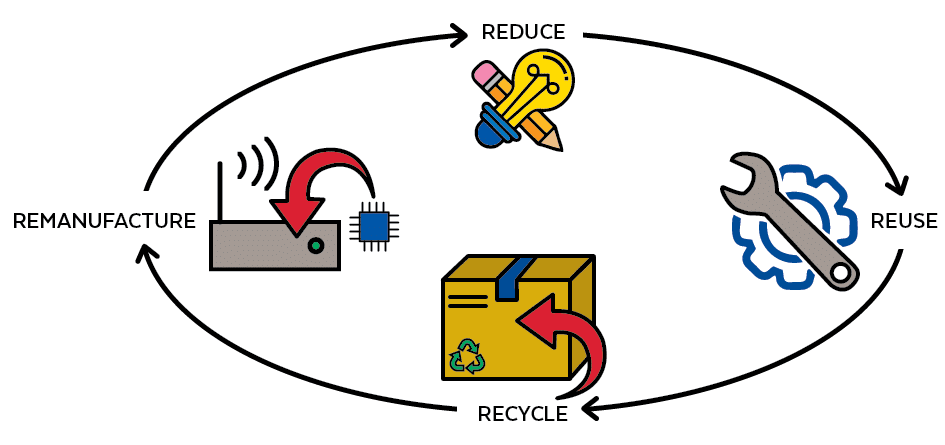

What is the Circular Economy?

The circular economy, one that thinks beyond the linear model, refers to a systemic approach to economic development. It is designed to benefit businesses, society, and the environment. It focuses on a regenerative design and seeks to separate the idea that economic growth requires the consumption of finite resources.

In a circular economy, manufacturing goes beyond the waste or disposal aspect and designs in ways a product or material may be reused or repurposed.

Principles

In a circular economy, economic development builds and rebuilds systemic health for large and small businesses, individuals, and the global community. The focus shifts towards the following three principles:

- Designing out waste and pollution from the beginning of the product development cycle.

- Keeping products and materials in use longer by planning for potential reuse at the end of the product’s lifecycle.

- Regenerating natural systems so they become renewable resources that can be sustainably used in the future.

If organizations are going to realize the potential of a circular economy, they must incorporate these principles into their business strategies.

Pillars

The Ellen MacArthur Foundation lists four pillars within the three principles of a circular economy. These pillars are designed to both reduce societal burdens imposed by a linear economy while also enhancing the lifespan of all resources.

Reduce

Reducing materials and resources used in product design and delivery is at the core of the circular economy. In 2019, 82.6% of the electronic waste disposal was uncertain, meaning the materials could be in landfills or polluting groundwater supplies. By creating devices that minimize the use of raw materials, manufacturers can reduce the amount of e-waste that could contaminate the environment. It is projected that the IoT market will top $1.5 billion by 2025, making reducing e-waste essential to developing a circular economy.

Reuse

IoT devices can move the circular economy forward by making devices easier to repair, repurpose, and reuse. Making it easier for people to upgrade a device rather than replace it means less e-waste. IoT devices also collect data about equipment performance, making it possible for organizations to repair equipment to extend its productive life.

Recycle

Recycling is a vital component of the circular economy. IoT technologies can improve waste management and recycling systems, but the industry also needs to look at recycling their devices. Many “smart” devices stop working because the software is not updated, or they become incompatible with the connecting network. IoT manufacturers need to create a program that is as easy as processing an Amazon return that enables consumers to return devices for recycling.

Remanufacture

Not all materials, of course, can be reused or recycled, but the devices may be remanufactured to minimize waste. For example, does a device need to be completely replaced, or is it possible to maintain the casing but remanufacture the internal components?

How IoT Technology Supports Circular Economy Principles

The digital transformation that many organizations are pursuing views technology as an enabler of change. One change is a technology’s ability to help decouple economic value from resource consumption. This systemic change uses IoT technologies to collect and assess data from throughout an enterprise. With access to real-time information, organizations can make informed decisions on how to deploy their assets. A recent article from the Ellen MacArthur Foundation entitled Intelligent Assets: Unlocking the Circular Economy Potential looks at the impact IoT technologies can have on an emerging circular economy.

The article points out that circular economy and intelligent asset drivers merge into an innovative crossroad that extends the useful life of assets, maximizes asset use, and regenerates natural capital. It’s impossible to predict what IoT technologies will look like going forward, but several companies have already deployed examples of how the interplay can have dramatic results.

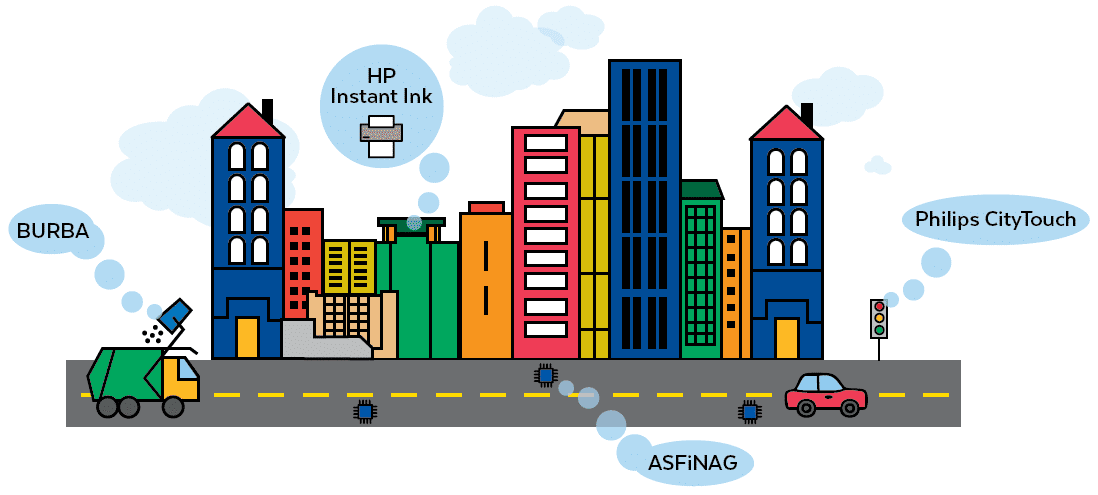

Smart Cities

Smart cities refer to an urban framework that uses technologies to develop, deploy and promote sustainable growth. It relies on a network of connected devices that transmit data to centralized locations to assist in better decisions to improve the quality of life for those living and working within the city’s boundaries. Whether it’s controlling lights or trash, IoT technologies are helping cities become more sustainable.

Burba

The BURBA project created an automatic system for intelligent waste management. The system consists of smart waste containers with RFID capabilities that can be used to identify individual trash receptacles.

The system includes electronics for data transmission so a management tool can receive the data and make decisions regarding the time of collection.

Adjusting refuse pickup to minimize wait times optimizes truck operations. There’s no need to wait in line at disposal plants or recycling facilities. Through metric analysis, the system can improve transportation efficiencies, diminish fuel costs and avoid overfull containers.

System advances support rapid deployment on containers and vehicle tracking. It can also redirect and reschedule waste collection, making real-time adjustments possible.

Cisco SmartROAD

Cisco partnered with ASFiNAG, a state-owned Austrian company, to devise a system for better monitoring of 2,200 kilometers of highway and 400 kilometers of tunnels. Using a fiber-optic network, the company connected more than 70,000 sensors and 6,500 traffic cameras to monitor the traffic on the roads.

The project used ruggedized switches and routers to communicate information using different radio standards in conjunction with Cisco’s communication system. The system provided feedback on road and traffic conditions to help route emergency vehicles and provide drivers with up-to-date information.

The Cisco solution uses a network of IoT devices to create a network infrastructure to connect various intelligent transportation systems to improve driving conditions on Austrian highways. The system reduces roadside incidents, improves traffic flow, and provides a centralized view of the road system in real-time.

Thousands of IoT devices collect information that can be used to eliminate congestion and reduce emissions. They can also report on road conditions so timely repairs can be made, minimizing operational costs.

HP Instant Ink

HP’s Instant Ink is a subscription service for individuals and small businesses. An HP printer is connected to an HP site that tracks the print cartridge levels to determine when a replacement is needed. When a cartridge runs out of ink, the printer notifies HP, and a new cartridge is sent without the end-user having to do anything. Along with the replacement, HP sends pre-paid envelopes for returning used cartridges, making its recovery and recycling program far more successful.

HP’s program demonstrates how recycling is possible within the consumer electronics sector. It allows HP to reuse their ink cartridges multiple times without placing a significant burden on the end-user. For a monthly fee, anyone can have replacements sent to them before they run out of ink. The closed-loop recycling program provides a service to the consumer while contributing to a circular economy.

Philips CityTouch

Jakarta needed a better way to manage its street lighting. So, with the help of Philips CityTouch, IoT devices called connector nodes were attached to street lights. Before the project, the city relied on conventional lighting without remote monitoring capabilities. With CityTouch, each light is connected so performance data can be collected. That information enables the city to monitor its infrastructure and adjust illumination levels to meet a district’s needs.

Over 400 street lights are connected, giving operators a comprehensive view of their city’s illumination. Using the data submitted in real-time, the city adjusts the illumination on a district-by-district basis. Now, Jakarta can lower illumination to conserve energy without impacting the individuals living in the area.

Smart Farming

Farmers are always looking for ways to improve crop yields and manage irrigation systems. When IoT technologies appeared, the agricultural industry adopted applications to control drones and monitor sensors. Sensors can now help farmers understand soil composition and forecast weather patterns. Libelium and OnFarm Systems are two companies with IoT solutions for smart farms.

Libelium

Livestock produces 14.5% of global greenhouse gas emissions. To help reduce these emissions, farmers are looking to IoT technologies. Working with organizations in Romania, Libelium deployed a system of sensors to monitor conditions in a stockyard. The structured data was used to provide recommendations to operators for better management of greenhouse gas emissions.

Using business intelligence, designers created different scenarios to determine the best conditions for reducing emissions. The IoT tools also allowed automated monitoring of animals to evaluate and improve conditions for optimal performance. By placing sensors in the livestock’s environment, farmers could monitor conditions without leaving the office.

SWIIM

Swiim purchased OnFarm’s water management system in 2018. The acquisition leveraged SWIIM’s platform for creating crop plans based on land characteristics and water resources with OnFarm’s dashboard to consolidate data. SWIIM ingests data from flow meters and measurement sensors on the farm. This information is then displayed on a dashboard using OnFarm’s application. The dashboard appears on any internet-connected device.

The OnFarm system retrieves soil moisture, pesticide records, temperature, and imaging data to give farmers a unified picture of the elements impacting productivity. Instead of looking through various systems, farmers can view an integrated dashboard that allows them to make data-driven decisions in real-time.

Smart Manufacturing

Smart manufacturing refers to fully integrated, collaborative systems that respond to changing demands and conditions in the factory, supply chain, and customer needs. Some of the industry’s biggest challenges can be addressed through IoT technologies. One area is supply chain visibility.

Caterpillar

Caterpillar uses IoT technology to maximize the lifecycle of its products. Instead of operating from a repair-after-failure mode, Caterpillar uses a repair-before-failure approach. Using IoT sensors, Caterpillar collects data on equipment performance and makes it available to the customer for analysis. The sensors can alert staff to possible failures before they happen, reducing downtime. But the data also extends the life of the equipment because potential failures can be addressed before they fail.

The longer equipment can stay in service, the better for the environment. Caterpillar’s approach to maintenance is one way to improve operations and the environment. Making the information available in real-time gives customers the ability to make informed decisions to help the environment.

Siemens AG

The Siemens AG plant builds automated machines for car manufacturers. About 75% of its factory is now automated, enabling its employees to operate and monitor the processes. The change has increased efficiency and reduced costs, but it has also enabled the facility to operate under the best possible environmental conditions and extend the lifecycle of a device.

The plant, which builds automated machines for car manufacturers, claims to be roughly 75% automated. Its 1,150 employees mainly operate computers and monitor the processes. According to the company, these changes have increased efficiency and reduced costs. They have also been able to minimize waste created during the manufacturing process.

Smart Future

IoT has moved the digital transformation towards a more sustainable economy. Whether these systems are monitoring water in an irrigation system or simplifying recycling of ink cartridges, IoT technologies are making it possible for society to migrate to a circular economy. As a company, Versa Technology supports these initiatives. So if you’re interested in learning more about Power over Ethernet (PoE) and last-mile IT networking technologies, contact us.